I cut a 3 foot long 10-24 size galvanized steel rod into pieces using a 14 inch bolt cutter...Then I attached the pieces of rod together using 1/2 inch copper strapping & 12-24 hex nuts...Then I coated all the nuts with Loctite Blue 242 which basically keeps the nuts from unscrewing themselves on the rods...This armature is fully movable, the fingers can bend at two joints, the thumb can bend inward towards the palm, the stem of the fingers can bend in towards the palm...

My next step is to cover each finger & the palm with mesh screening & tie that on with copper wire & a pliers...From there, I am considering dipping the hand in Plasti Dip, a movable rubber dip that coats the whole hand but lets it move...

Not sure what colour I will be using for the final colour...I feel that flesh tones are too realistic & would prefer something that states that the hand is indeed a fake, so as not to scare any casual onlooker...Considering blue...Or white white...

Joseph likes the way it looks now so much he doesn't want me to do any more work...He likes the Terminator Steampunk feel I guess...Hmmm...The neat thing about having different pieces in different states of finish is that people who want to try to make a prosthetic limb themselves can actually see how it is done, without even any welding...If I cover up my tracks, it won't be didactic anymore really...

I was thinking that prosthetic limbs are so expensive to buy, that if I could show others how to make them themselves, people who need them could attempt a DIY version...It would be cool to make your own, no? Just a quirky thought...

Ok, so in many countries on this planet, they have outlawed the sale of any cement bags that weigh more than 25 kilograms...A 20 kilogram bag of cement, for those who operate in American, is about 44 pounds (lbs)...Most of those countries who ban the sale of a more than 25 kg bag of cement have 20 kg bags for sale, not 25 kgs...Though they could legally sell the 25 kg bags...

Canada has no such ban...This means that cement companies can make & sell cement here in the 40 kg bag...This means that retailers buy those 40 kg bags legally...88 lbs...This means that contractors are buying those 88 lb bags & that construction workers are forced to try to lift a 88 lb bag of cement...

Each back injury per year is estimated to cost a company 25 thousand dollars...Now, buying cement in smaller 20 kg bags (44 lbs) will cost a company more money in the very short term...But the reduced incidence of back injury will save a construction company huge in the slightly longer term...Plus, fewer people will have back injuries if maximum weights are enforced legally...

I spoke to St. Mary's cement in Toronto about this...Frank said that 6 years ago (2006), he produced "BackSaver" cement in 20 kg bags...But there was no legislation to support his bold move...So the retailers didn't buy any of it because they didn't have to...This meant that the cement sat in his warehouse for a year & a half & he ended up taking a huge loss on it by giving it to cement recyclers...

None of his backsaving cement ever hit the retail market in Canada...None of the retailers had vision...None of the contractors had vision...All they could see was that buying a 40 kg bag of cement was cheaper in total costs than buying several 20 kg bags...So Canadian masons suffer back injuries...Still...While masons in other countries are working peacefully & happily & safely, Canadians are still idiotically trying to lift 88 lb bags of cement & injuring their backs, sometimes permanently...

Is it because construction workers are disposable people that we haven't legislated about this? Why is Canada lagging behind? Australia, England, Ireland, are three countries who are, as Nickelback says so succinctly, are : "All in, Balls out"...

When are Canadians going to step up to the plate?

I write this because I have been working with white cement & I cannot buy a 20 kilogram bag here in Toronto...Because of the lack of laws concerning this, there is NO way to buy a 44 lb bag of white cement here in Toronto...This is not fair...I am a woman...I am very very strong but there is NO way I can dead lift 88 lbs of white cement...No way...Which means I can't source my artist materials for ferrocement sculpture...I have been getting a kind building supply person to break open bags & pour them into smaller sized bags...But he is running out of the smaller size cement bags & I am running out of lack of embarrassment to ask for such a favour for so little money....If smaller cement bags were available at retail stores in Toronto, people would buy them...But they won't become available unless our government legislates about what is too heavy...And every Health & Safety Board on the planet agrees that more than 25 kgs is too heavy...Even Lou Ferrigno doesn't want to lift a 40 kg bag of white cement...Even though he can...

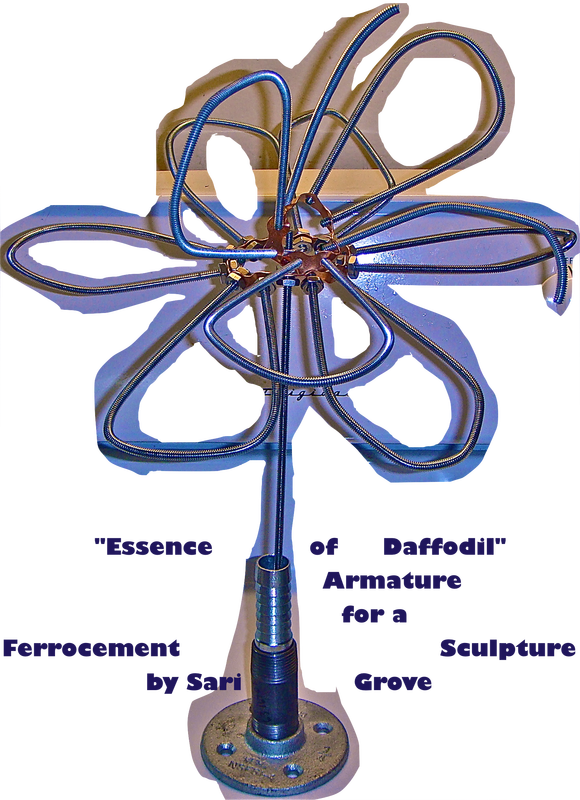

So Good Friday is tomorrow...Easter is on Sunday...Today is Thursday April 5, 2012...I have begun the armature for Essence of daffodil in honour of the spring season & all that it brings...Also, the Bee sculpture needs a flower to keep it company...This is a no-weld design...My invention...I used 10-24 galvanized steel rods...12-24 hexagonal stainless steel bolts...(I found the 10-24 bolts were a tight squeeze so I went up a size for the bolts)...1/2 inch copper strapping, the one with the holes in it that exactly fit these size rods...A black steel 3/4 inch nipple (yes it is called a nipple)...A 3/4 inch steel TEE to go in the nipple...& a 3/4 inch FLANGE to stick the nipple & the tee IN...This makes a strong armature to put cement on...Of course my next step will be to reinforce everything I have put together, checking all connections & tightening with pliers where I can...Then I tie on a screen mesh to the rods so that the cement has somewhere to lay upon...

RSS Feed

RSS Feed