http://grovecanada.typepad.com/ I am keeping more notes on my Ferrocement process over here on this Typepad blog...Feel free to visit...

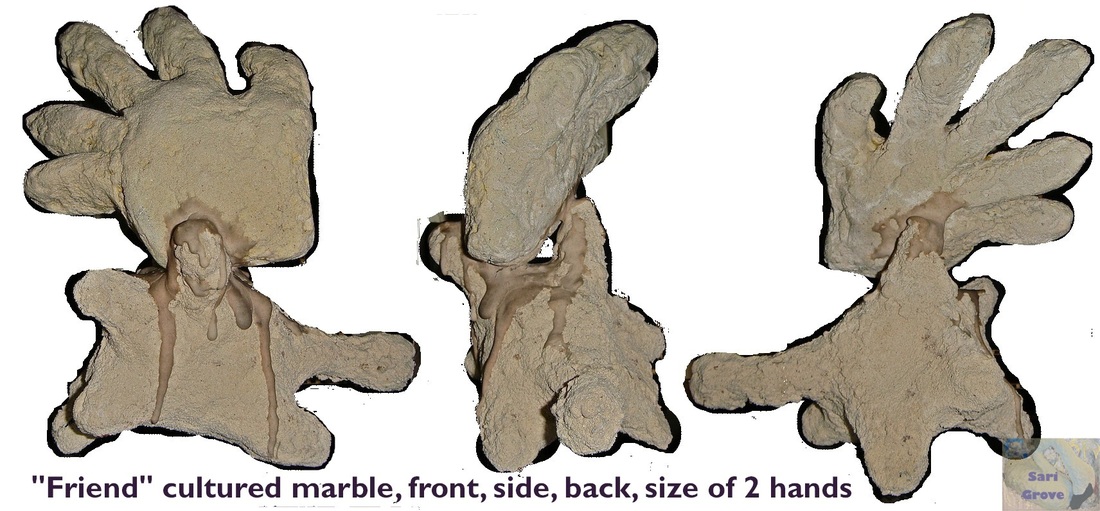

Below "FRIENDS"...cultured marble...

Cultured marble: Aragonite sand from the reptile section at Petsmart at laird & Eglinton...Plus Weldbond white liquid glue from canadian Tire paint section Davenport & Yonge...Plus 3/4 inch glass fibers alkaline resistant from Kreitmaker on Industrial street (also near Laird & Eglinton)...Plus water...

The Putty I used to attach the two pieces together: Baby Powder(from the Shoppers Drug Mart at Bloor & across from the museum, the Royal Ontario Museum) which is a pure talc one, which is actually magnesium silicate, added to Circa 1850 powdered resin glue available at Home hardware at Dupont & Shaw...Note: Magnesium Silicate (Baby powder talc) makes a cement that removes more carbon dioxide from the environment than it excretes in its making...It is GOOD for the environment...Normal cement excretes more carbon dioxide than it absorbs, which is why environmentalists sometimes pooh pooh cement...The only question is if the talc magnesium silicate cement is strong enough...Suggestions are to try a magnesium silicate cement for no-weight bearing loads for now- adding glass fibers will reinforce those applications for greater strength...Certainly arts & crafts people can use baby powder talc instead of regular cement- you will notice right away that the air smells fresher where you work, instead of worse when you use regular cement...

RSS Feed

RSS Feed